RFID wristband can be widely applied in swimming pool, theme park, marathon, hospital management, membership management and loyalty program and access control management etc. Besides, Meihe provides programming and encoding services which exactly fit customer’s programming or encoding requirements.

|

Panasonic Compressor,Copeland Semi-Hermetic Compressor,Refrigerant Gas Suppliers China | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

پیغام مدیر سایت سلام دوست من به سایت Panasonic Compressor,Copeland Semi-Hermetic Compressor,Refrigerant Gas Suppliers China خوش آمدید لطفا برای استفاده از تمامی امکانات

دانلود فایل , شرکت در انجمن و گفتگو با سایر اعضا در سایت ثبت نام کنید Vacuum Transformer Oil Purifier is specially used for purification of dielectric oil such as transformer oil. Its function is to remove impurities, moisture and gas in the oil and improve the quality and service life of the oil. Transformer Oil Purifier is widely used in electric power, electric equipment installation and maintenance, and are one of the important equipment to ensure the safe and stable operation of equipment. Following is introduction of principles, applications and maintenance methods of transformer oil filter machine. 1. Principle analysis Transformer Oil Filter Machine is mainly based on the filtration principle, generally using pressure filtration or vacuum filtration. Pressure filtration is to use pressure to pass oil through the filter. The interior of the filter is generally composed of a variety of filter elements with different pore sizes, and the purification effect is achieved through step-by-step filtration. Vacuum filtration uses a vacuum pump to suck oil into the filter and separates impurities through filter media such as filter bags. The working process of the Transformer Oil Filter Machine includes: the oil pump sucks the oil to be filtered into the filter, separates impurities, water and gas through the filter medium inside the filter, and the filtered clean oil is discharged from the filter outlet to complete the filter process. 2. Application Transformer Oil Dehydration Plant is also widely used in electric power, petrochemical, chemical and other fields, mainly used to purify transformer oil, transformer oil, hydraulic oil and other industrial oils. In the power industry, the transformer oil dehydration plant can ensure the safe and stable operation of power equipment; in the petrochemical and chemical industries, the oil filter can improve the working efficiency and service life of the equipment. 3. Maintenance When using a Transformer Oil Dehydration Plant, first check whether the power supply and pipeline connections of the equipment are normal to ensure that the equipment is in a safe and stable operating state. At the same time, the appropriate filter medium should be selected according to the nature and quality of the oil to be filtered, and the filter medium should be replaced regularly. In terms of maintenance, the transformer oil purifier should be inspected and maintained regularly, such as cleaning the filter, replacing the seal, etc. At the same time, the electrical part of the equipment should be checked regularly to ensure the safety of equipment. When the transformer oil filter machine is not in use for a long time, the oil inside and outside the equipment should be drained to avoid problems such as oil deterioration due to long-term use.

تاریخ : سه شنبه 07 آذر 1402 نویسنده : panasoniccompressor l بازدید : 45

Vacuum Transformer Oil Purification Machine is a professional equipment used in high-voltage equipment such as transformers, substation, etc. Its main function is to remove impurities and moisture in the insulating oil, maintain the purity and insulating properties of the oil, thereby Transformer Oil Purification Machine can ensure the normal operation of the equipment and prolonging the service life of the equipment. insulating oil plays an important role in insulation and cooling in high-voltage equipment. However, over time, insulating oils can gradually become contaminated due to equipment aging, moisture ingress, accumulation of solid particles, etc. These pollutants can cause electrical partial discharge, breakdown, and equipment failure, thereby affecting the reliability and safety of the equipment. Therefore, it is very important to use Insulation Oil Purifier for purification of the insulating oil regularly. The vacuum Insulation Oil Purifier for insulating oil uses vacuum technology and oil filter elements to remove impurities, oxidation products and moisture in insulating oil. The working principle of Transformer Oil Treatment Machine is to establish a vacuum environment to evaporate the gas and water in the insulating oil, and to trap solid particles through the oil filters. This can effectively improve the cleanliness and insulation performance of the insulating oil and reduce the risk of equipment failure. The Vacuum Transformer Oil Purification Machine has the following advantages: 1. Improve insulation performance: Insulation Oil Purifier remove impurities and moisture in the oil, so that the insulation performance of insulating oil is improved, thereby reducing the risk of partial discharge and breakdown of equipment. 2. Extend equipment life: Transformer Oil Treatment Machine can maintain the purity and stability of insulating oil, delay the aging speed of equipment, and prolong the service life of equipment.

3. Reduce maintenance cost: The filtered insulating oil can better protect the equipment, reduce the failure rate and maintenance frequency of the equipment, and thus reduce the maintenance cost. 4. Environmental protection and energy saving: Physical methods are used by Transformer Oil Purification Machine for filtration treatment without adding chemicals, which meets environmental protection requirements. In addition, the insulating oil after purification can be reused, reducing resource consumption. Vacuum Transformer Oil Treatment Machine plays an important role in maintaining the normal operation of high-voltage equipment and prolonging the life of the equipment. Regular filtering of insulating oil through insulation oil purifier can reduce the risk of equipment

تاریخ : سه شنبه 07 آذر 1402 نویسنده : panasoniccompressor l بازدید : 43

High speed nail making machine In order to ensure the stability of the performance of the high-speed nail making machine, routine inspection is essential. Today, the editor will tell you the basic content of the routine inspection of the high-speed nail making machine.

1. Electrical system 1) Whether the emergency stop button is sensitive and reliable; 2) Whether the motor is running normally and whether there is any abnormal heating phenomenon; 3) Whether the wires and cables are damaged; 4) Whether the limit switch and button function are normal and the action is reliable;

2. Control system The manual wheel must be pulled out before normal starting;

3. Lubrication system 1) Is the oil pump working normally? 2) Whether the liquid level of the oil pump meets the specified requirements; 3) Whether each lubrication point is properly lubricated; 4) Whether the quality of lubricating oil is qualified;

4. Transmission system 1) Whether the belt tension is appropriate; 2) Whether there are cracks on the surface; 3) Whether the pulley is running normally.

تاریخ : دوشنبه 13 شهریور 1402 نویسنده : panasoniccompressor l بازدید : 49

In the production process of the nail making machine, it is often encountered that the service life of some customers' knives is short. Some customers are also complaining that they have to be replaced after not being used for a long time. There is also a reason for this. The nail making machine manufacturer will introduce to you 4 common reasons for the rapid damage of the nail making machine tool. 1. Material, excellent material If the material is too hard, it will cause the tool to wear quickly; the material has defects such as dust inclusions and seams. 2. The reason of the tool itself Some cutting edges do not meet the requirements. It should be noted here that the applicable cutting edges are also different for materials with different hardness and strength. 3. The machine adjustment is not in place The clamping force is insufficient or too tight when the wire feeder knife or wire feeder roller feeds the wire. At this time, we should adjust the wire feeder knife so that the wire feeder can reliably feed the wire, and replace the worn parts of the wire feeder. 4. The pay-off frame is not suitable or the rotation of the turntable is not flexible

تاریخ : دوشنبه 13 شهریور 1402 نویسنده : panasoniccompressor l بازدید : 47

Introduction:

SSS Hardware International Trading Co., Ltd. is a high-tech foreign trade company specializing in the production of high-speed nail making machines. This article explores the countries with the highest demand for high-speed nail making machines and discusses future directions for their development.

b. Sustainability: Environmental concerns are driving the demand for sustainable manufacturing practices. High-speed nail making machines can contribute to sustainability efforts by minimizing material waste and optimizing energy consumption. SSS Hardware International Trading Co., Ltd. can focus on developing eco-friendly machines to cater to this growing market segment. c. Expansion into Emerging Markets: Emerging economies in Africa, South America, and other parts of Asia are undergoing rapid development, presenting untapped opportunities for high-speed nail making machines. By expanding their reach into these markets, SSS Hardware International Trading Co., Ltd. can establish a global presence and capture new market share. d. Customization and Specialization: To stay competitive, high-speed nail making machines can be customized to meet the specific requirements of different industries. SSS Hardware International Trading Co., Ltd. can explore niche markets and develop specialized machines that cater to unique applications, such as automotive, furniture, or woodworking industries. Conclusion:

تاریخ : دوشنبه 13 شهریور 1402 نویسنده : panasoniccompressor l بازدید : 42

The Global Prospects of High-Speed Nail Making Machines Introduction:

Conclusion:

تاریخ : دوشنبه 13 شهریور 1402 نویسنده : panasoniccompressor l بازدید : 39

Transformer oil is an important electrical insulating oil used to insulate and cool high voltage transformers. Long-term use will lead to the accumulation of impurities and moisture in the oil, reduce the insulation and thermal conductivity of the oil, and adversely affect the normal operation of the equipment. Therefore, using Transformer Oil Filtration Machine to do the efficient purification of dielectric oil becomes particularly important. High efficiency Transformer Oil Purification refers to the use of specific filtration equipment to thoroughly removing impurities and water in transformer oil to achieve the effect of cleaning new oil.

The importance of efficient Transformer Oil Purification is: 1. Ensure the insulation performance of the oil. Transformer oil as an insulating medium, insulation performance is its most important performance. The accumulation of impurities in the oil will lead to a decline in the insulation performance of electrical equipment, and when the dielectric strength of oil does not meet the requirements, there will be a breakdown phenomenon causing equipment failure.

2 Eliminate moisture from transformer oil. Once the moisture in the transformer oil exceeds the specified standard, it will reduce the insulation performance of the oil and the strength of the medium. At the same time, the moisture may also lead to the oxidation of the transformer oil, thereby reducing the oxidation resistance of the oil.

3 Extend the life of electric equipment. Through the efficient Transformer Oil Purification, the impurities and moisture in the transformer oil are completely removed, which can effectively extend the service life of the electric equipment.

The Transformer Oil Filter Machine used for high-efficiency Transformer Oil Purification mainly includes the following types: 1. Double Stages Vacuum Transformer Oil Filtration Machine. it is a kind of equipment that uses high vacuum and micron filter to separate impurities and moisture in transformer oil. The high vacuum can discharge the water and air in the oil, and the micron filter can remove the solid particles and colloidal substances in the oil. The high Transformer Oil Filter Machine has the advantages of large processing capacity, high efficiency and good treatment effect.

2. Centrifugal type transformer oil purification, it uses centrifugal force to separate impurities and water in the oil. It can separate the solid particles and water in the oil to achieve the effect of filtration. Centrifugal type transformer oil filter machine has the advantages of low manufacturing cost, less space and strong automatic production capacity.

3· Multistage Transformer Oil Filter Machine. It is used for transformer oil purification in multiple stages, and each filtration stage can remove a certain amount of impurities and moisture. The multistage Transformer Oil Purification can ensure the cleanliness and insulation performance of the oil to a certain extent.

High efficiency Transformer Oil Filtration Machine plays an important role in maintaining the long-term safe operation of equipment and extending the life of electric equipment. When carrying out transformer oil purification, it is necessary to select the suitable filtration equipment, and carry out regular maintenance and replacement of the filter element to ensure the effective operation of the equipment.

تاریخ : چهارشنبه 25 مرداد 1402 نویسنده : panasoniccompressor l بازدید : 36

The selection for oil pumps of Vacuum Oil Purifier is main according to which type of oil is applied to the Vacuum Oil Purifier, following is recommendation Gear pump: Gear pump is commonly used in low-pressure systems and is not sensitive to oil pollution, so it is commonly used in ordinary lubricating oil purifier, turbine oil purifier, hydraulic oil purifier and single vacuum Insulation Oil Purifier. Because lubricating oils generally contain relatively more impurity quality, and the cost is moderate. The centrifugal pump is insensitive to impurities, has few wearing parts, and is convenient for management and maintenance. However, when operating below the rated flow rate and small flow, the efficiency of the pump is low. It is suitable for conveying various liquids with low viscosity, and viscosity has a great influence on the performance of the pump. Therefore, the frequency of vacuum oil purifier choosing to use centrifugal pump is not large. Generally, when used for double stages High Vacuum Transformer Oil Purifier, the centrifugal pump will be selected due to temperature or environment. Screw pump: Because of its compact structure, few parts, easy assembly and disassembly, and low-pressure pulsation, low noise, long life, the reason for choosing a screw pump is that its flow loss during operation is small, and the operation is stable. More common in the user to choose double stages vacuum Transformer Oil Purifier use, common in the filtration of insulating oil, dielectric oil, it will not produce harmful gases because of this pump. The above briefly describes several common oil pump types in vacuum oil purifier, the user's oil to be treated is different, the oil pump configuration changes,

تاریخ : چهارشنبه 25 مرداد 1402 نویسنده : panasoniccompressor l بازدید : 36

DVTP double stages high Transformer Oil Purifier adopts advanced degassing elements, which can greatly improve the degassing efficiency, adopts advanced photoelectric control defoaming device, and adopts mechanical and electronic control type and overpressure alarm device for oil level control, which can realize automatic operation. The oil inlet and outlet have the function of interchanging, and the oil inlet and outlet can be exchanged at will through the valve control during operation, without disassembling the oil pipe. The use of low-power high-density electric heating elements, with overheating protection system, the Vacuum Transformer Oil Purifier in any case will not cause oil deterioration phenomenon, the whole system without cooling, winter use, no need to replace the filter element without tool disassembly. Different liquids have different saturated steam pressure, at a temperature of 70 ° C, water begins to boil at about 30000a force, while oil can boil at a low pressure of 5Pa. The saturated vapor pressure of oil is much lower than that of water at the same temperature. Therefore, Vacuum Transformer Oil Filtration Machine by vacuuming the pressure of the liquid surface of the oil is reduced to below the saturated vapor pressure of water, then the water in the oil will be vaporized by scraping and overflow from the oil in the form of steam. Precautions for Transformer Oil Purifier operation: 1. Vacuum pump work, should pay attention to the oil label display of the oil (oil should be on the oil label line), if found vacuum pump oil more water or too dirty, to replace in time, so as not to affect the service life of the vacuum pump. 2. When the cooler is found to have more memory water during operation, it should be discharged in time. 3. The change in the value of the pressure gauge, in the normal Oil Filtration Process, if the pressure is found to be >0.3Mpa, the filter should be cleaned or replaced in time. 4, the filter screen of the initial filter should be often removed and cleaned, keep clean, so as not to clog and cause insufficient oil or too high pressure. When it is found that the oil intake of the Transformer Oil Filtration Machine is small, it indicates that the impurities of the filter screen of the initial filter increase, and it needs to be cleaned immediately. 5, at any time during the operation of the pump and the corresponding motor running noise is normal, if found abnormal should be immediately excluded, so as not to burn the motor or affect the life of the oil pump. 6, when the Oil Filtration Process is stopped and not used, the vacuum pump oil should be drained and new oil should be injected.

تاریخ : چهارشنبه 25 مرداد 1402 نویسنده : panasoniccompressor l بازدید : 33

Transformer Oil Purification Plant is a commonly used electric equipment maintenance instrument, which mainly is used for oil purification process of transformers, reactors, capacitors and other power equipment. Transformer Oil Purification Plant can provide a stable and efficient oil purification environment for power equipment, and provide a guarantee for the safe operation and life extension of electric equipment. The working principle of Transformer Oil Filter Machine is to treat the transformer oil through micron filter and vacuum dehydration, degassing system, which removes impurities and moisture from it. The Transformer Oil Purifier can set parameters such as filtration accuracy, filtration speed, heating temperature to meet the needs of different experiments.

In the maintenance of power equipment, Transformer Oil Filter Machine is widely used in various types of power equipment. For example, it can be used for transformer maintenance, and the transformer oil can be purified to remove impurities and moisture from it, thus ensuring the safe operation and extended life of the transformer. In addition, the Transformer Oil Purification Plant can also be used for reactor maintenance, which can remove impurities and moisture in it, so as to ensure the safe operation and extended life of the reactor. In addition, the Transformer Oil Purifier can also be used for capacitor maintenance, which can filter the capacitor oil to remove impurities and moisture in it, so as to ensure the safe operation and extended life of the capacitor. The application of Transformer Oil Purifier in the maintenance of power equipment provides us with a more stable, efficient and reliable oil purification environment, which helps us better realize the maintenance and maintenance of power equipment. At the same time, the high efficiency and low cost of Transformer Oil Purification Plant also provide a more convenient and fast tool for the maintenance of power equipment. In addition, the diversification and flexibility of transformer Oil Purifier also provide more comprehensive and perfect solutions for oil purification in different fields and different types of electric equipment.

تاریخ : چهارشنبه 25 مرداد 1402 نویسنده : panasoniccompressor l بازدید : 35

With the continuous development of industrialization, the requirements for machinery and equipment is also increasing. Among them, Oil Purifier in the lubrication system is widely used in many fields. As an efficient, reliable and environmentally friendly equipment, the Vacuum Dehydration Oil Purifier has become one of the favored and valued products in the market. The Vacuum Dehydration Oil Purifier is mainly used to remove dissolved water or emulsion trace water contained in the oils, so as to achieve the goal of extending the service life of the oil and improving the operating efficiency of the lubrication system. The main principle of Oil Purifier is to physically remove the oil containing impurities and pollutants and remove the moisture contained therein.

Firstly, Vacuum Dehydration Oil Purifier adopts advanced precision filtration technology, which can effectively remove particles, colloidal substances and other solid impurities with a diameter greater than 1μm in the oil. This avoids wear and clogging of the internal components of the equipment by these particles, ensuring the continuous and stable operation of the system. At the same time, the quality of the purified oil is improved, so as to ensure the normal operation of the equipment. Secondly, the Vacuum Dehydration Oil Purification System also has a good dewatering effect. By using highly efficient adsorption materials and vacuum evaporation technology, the solubility and trace emulsion moisture contained in the oil can be removed. This dehydration process can prevent moisture, acids, etc. and can effectively improve the oxidation resistance of the oil and reduce foam phenomenon. In addition, in terms of operation, Vacuum Dehydration Oil Purification System is also very convenient and easy to use. In general, the user only needs to transport the lubricant to be treated into the machine and set the appropriate parameters according to the requirements to start the operation. In addition, Vacuum Dehydration Oil Purifier is also equipped with an intelligent control system and safety protection devices, which can monitor the working status in real time and automatically stop the alarm during operation to ensure personnel safety and stable operation of the vacuum dehydration oil purification system.

تاریخ : چهارشنبه 25 مرداد 1402 نویسنده : panasoniccompressor l بازدید : 19

We recommend a new multi-functional electric road cutter,which is a versatile tool that is used for cutting asphalt, concrete, cement,wood and other hard surfaces. This machine is powered by an electric motor 3200W and uses a diamond blade to cut through tough materials. on construction sites and in road repair projects. Some of the key features of this machine include: 1.Versatile Blade: The diamond blade used in theelectric road cutter is versatile and can be adjusted to cut at different angles.This makes it possible to cut curves and shapes in hard surfaces. thathelps to control the amount of dust generated during cutting. This makes it safer and more comfortable to operate the machine. comfortable handles and a lightweight design that makes it easy to maneuver. be used for a wide range of applications. This makes ita versatile tool that can be used for cutting roads, sidewalks, driveways, and other hard surfaces.

تاریخ : پنجشنبه 12 مرداد 1402 نویسنده : panasoniccompressor l بازدید : 26

Detuo supply different small portable concrete mixers like: Vertical type,Hand push type,Gasoline engine type,Heavy duty type. they are usually feature a rotating cement mixer bowl, a motor that rotates the mixer bowl and the handle that allows the operator to shift the position of the cement mixer bowl to pour out the cement or concrete once ready. It can either be mobile or stationary and can be mounted on trailers or trucks. Purchasing the right small cement mixer can be challenging because there are so many models on the market. Small concrete mixer models are usually used at construction sites for getting into hard to reach areas and mixing cement. Although cement and concrete can be blended by hand, construction projects will be completed faster with a large or small cement mixer. Our concrete mixer are very popular in market, customer are from European countries,South American, Middle Eastern Countries etc. Please check our products pictures as below:

تاریخ : پنجشنبه 12 مرداد 1402 نویسنده : panasoniccompressor l بازدید : 18

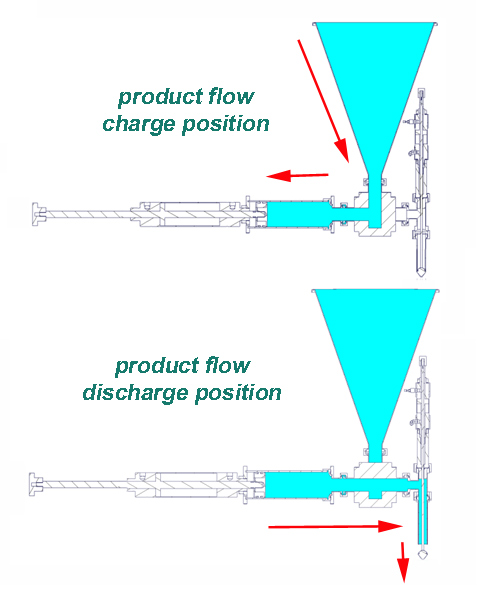

As one of the most widely used filling equipment in the food industry, a piston filling machine has been proven to be highly efficient, accurate, and reliable. With its two to sixteen heads, it can fill liquids and sauces into bottles, jars, and containers without spilling, dripping, or wasting any product.

تاریخ : پنجشنبه 08 تیر 1402 نویسنده : panasoniccompressor l بازدید : 18

Choosing a filling machine involves several factors that you need to consider based on your specific requirements. Here are some steps to help you choose the right filling machine:

تاریخ : پنجشنبه 08 تیر 1402 نویسنده : panasoniccompressor l بازدید : 18

Automatic Gas Cartridge Aerosol Filling Line is the most typical and popular automatic aerosol filling line for gas cartridge. Automatic gas cartridge aerosol filling line consists of Automatic Cassette Valve Inserter for Gas Cartridge, Gas Cartridge Filling Machine, Aerosol Checkweigher, Automatic Cap Press, Ink Jet Printer. Automatic Cassette Valve Inserter for Gas Cartridge is the first & unique cassette valve inserter in China launched by us in 2017. Automatic Gas Cartridge Filling Machine consists of 1 vacuum head, 1 valve sealing head and 3 gassing heads. It’s suitable for can diameter ranging from 35mm to 65mm, can height ranging from 80mm to 330mm, 1” international standard cassette aerosol valve. Easy and convenient in operation & maintenance. It’s the best choice for automatic gas cartridge aerosol product production to reach 2,000-3,200 cans/hour.

تاریخ : چهارشنبه 07 تیر 1402 نویسنده : panasoniccompressor l بازدید : 23

Spray paint(aerosol paint) is usually made up of aerosol can, aerosol valve, filler (paint) and propellant. After high-pressure filling through a special process, the paint becomes easy to spray. So it is also called manual paint. The spray paint is used widely. With the development of economy in recent years, it is not just used for paint re-patching, but for various industries such as: mold, industrial machinery, toy, crafts, musical instrument, construction, steel structure, advertising, publicity, signboard and graffiti. Even in some less industrialized grasslands and pastoral areas, it is said that different color of spray paint is used to distinguish every farmer’s herds of cattle and goats. The aerosol spray paint usually consists of aerosol can, aerosol valve, filler (paint) and propellant, as well as the ball that is put in the aerosol can for stirring. Aerosol spray paint filling solutions can be selective, take a look at following alternative solutions. 80-120CPM High Speed Automatic Spray Paint Aerosol Filling Line adopt Y shape design layout, using 2 sets of AF-50A Automatic Aerosol Filling Machine and 2 sets of Aerosol Valve Inserter for filling, valve inserting, crimping and gassing. The end parts will adopt high speed machines including AWC-120 Aerosol Can Check weigher,AWT-3500 Water-bath Leakage Tester, AWP-100 Automatic Actuator Placer and ACP-100 Automatic Cap Presser, make the aerosol production line to reach the high speed at 120 cans per minute.

Main Features:

تاریخ : چهارشنبه 07 تیر 1402 نویسنده : panasoniccompressor l بازدید : 26

There are six main classifications about the characteristics of electric forklifts, which are: electric pallet forklift; electric pallet stacker forklift; reach truck; universal electric forklift; four-way electric forklift; VNA narrow aisle forklift. The following is an analysis of the market range of the six features. (1) Electric pallet handling forklift truck The main function of electric pallet forklift truck is to achieve point-to-point movement of pallet goods on a flat surface, therefore there is no gantry lifting system, it is suitable for places that focus on handling and do not need stacking, there are three types of self-propelled, stand-and-drive and sit-and-drive forklift trucks with different costs. (2) Electric Pallet Stacker Forklift Electric pallet stacker forklift is a kind of light indoor lifting and stacking equipment, focusing on stacking function, because of the light body. It is suitable for the handling of small and light materials in floor-type warehouses or other narrow places. (3)Forward moving forklift truck The lifting mechanism of the forward moving forklift truck can move back and forth in the longitudinal direction of the forklift truck. When forking goods. The center of gravity of the goods falls within the four pivot points formed by the wheels. Therefore, the forklift truck has better flexibility, high lifting safety and stability. The load range is usually 1-2.5 tonnes and the lifting height can be up to 12 metres. However, due to the small wheels. Passing is restricted, and because of the complex structure, the cost is higher, so it is suitable for places with narrow space and high lifting height requirements, and is mostly used in high-rise storage depots. (4) Universal electric forklift truck The universal electric forklift truck can travel in all directions. In addition to the main features of counterbalanced forklift trucks, the three wheels can travel in ~ direction at any angle in unison, so this model is flexible in steering, and after forking goods, it can turn in place and move the forklift truck in any direction according to the restrictions of the site. This model solves the problem of steering long materials in narrow spaces, greatly saving space, and can achieve diagonal palletizing and demolition in trains and carriages. (5) Four-way electric forklift truck The four-way electric forklift truck integrates the functions of the forklift truck, side fork and counterbalanced forklift truck in one. In terms of construction. It is basically the same as the front-shift forklift truck, the door frame is located between the front and rear wheels, and there are two legs in front of the truck in the shape of arms, and the front end of the legs is equipped with supporting wheels, and the goods can move back and forth with the door frame in the longitudinal direction of the forklift truck. When forking and unloading, the forks are extended, and after forking and unloading the goods, the forks are returned to the middle position close to the car body, so the stability of forklift truck driving is greatly improved. The difference with the forklift truck is that the two load-bearing wheels at the front of the fork legs of the four-way electric forklift truck can be turned back 90° by the steering mechanism. The minimum aisle width can usually be less than 2 metres. However, due to the complex structure, the cost is higher. (6) VNA narrow aisle forklift truck The main feature of the VNA narrow aisle forklift truck is that the gantry lifting mechanism can be rotated in three directions, so that the car body does not need to be rotated when stacking, but only the goods or the gantry needs to be rotated. The width of the aisle is therefore considerably reduced. At present the minimum aisle width is below 1.8 metres. But at the same time. The width of the aisle also depends on the size of the pallet. For example, it is still not possible to reduce the aisle width when handling long goods. In addition, the overall weight required to ensure the stability of the lateral stacking is much greater than that of a three-point counterbalanced electric forklift truck and therefore slightly less economical.

تاریخ : دوشنبه 22 خرداد 1402 نویسنده : panasoniccompressor l بازدید : 26

The main advantage of counterbalanced electric forklifts is that they are very efficient and easy to use. They require minimal maintenance and can be used in a variety of applications. They are also more maneuverable than other types of forklifts, making them ideal for tight spaces. Counterbalance electric forklifts are also quieter than their gasoline or diesel counterparts, which makes them a good choice for indoor operations. Additionally, they are more environmentally friendly since they produce fewer emissions than other types of forklifts.

تاریخ : دوشنبه 22 خرداد 1402 نویسنده : panasoniccompressor l بازدید : 21

Table call bell can send the calling signal to a receiver, call waiter when need help. With 12V 23A battery, Round shape, belongs to wireless calling system. OEM acceptable

How to work of wireless call waiter system Wireless call system is widely used in service area of restaurant, hotel, cafe, bar, casino, hospital and so on. wireless restaurant table call system consists of call button for guest/patient use and signal receiver for waiter/nurse use. When the guest need any service, they can press the button on the table, the table number will be showed on the RECEIVER of watch or display screen with clear “dingdong” sound or vibration. So the waiter could offer service very timely. Application : Tea or Coffee House, Restaurants, Hotel Conference Rooms, Executive Dining Rooms, Spas and salons Health and Fitness clubs, Hospitals Health Clubs, Offices Massage House, Nightclubs, Bowling Alleys, Churches, Casinos, Golf Country Clubs, Bank, Medical Clinic, Fitness center, Chess and card room, Relaxation club, Kitchen, Confinement center, Super Market, Church

تاریخ : دوشنبه 07 فروردین 1402 نویسنده : panasoniccompressor l بازدید : 51

This Venturi oxygen mask is an oxygen kit that enables the user to regulate the amount of oxygen supplied from an oxygen tank cylinder. It comes with seven separate color-coded diluters which represent oxygen percentages of 24, 28, 31, 40, 50, and 60%.

تاریخ : دوشنبه 07 فروردین 1402 نویسنده : panasoniccompressor l بازدید : 28

Rebenet RGR24 commercial gas range with ov has four en30,000-BTU open burners, which can cook several pots or pans simultaneously. Cast iron grates transmit heat efficiently t000-BTU oven, saving kitchen’s space for other applianceso the pan from the burner. There is a crumb tray beneath the burners that catces and conthains loose food matter. This commercial style gas range’s base houses a 31,.

Our Advantages Guangzhou Rebenet Catering Equipment Manufacturing Co., Ltd is one of the leading manufacturer of commercial kitchen equipment in Guangzhou China. Our advantages are as below: 1. 6+ years of manufacture experience. 2. Over 20,000 square meters of factory area and with more than 250 skillful workers.

تاریخ : دوشنبه 07 فروردین 1402 نویسنده : panasoniccompressor l بازدید : 49

New coronavirus Antigen test is used for the qualitative detection of novel coronavirus (COVD-19) antigen in human throat swab and nasal swab samples

. . Feature

Test procedure Insert the swab (after collection) into the sampling tube containing individual lysis buffer. Rotate the swab against the inner tube wall 10times and squeeze the swab from the outer tube wall 5 times to completely dissolve the sample in the buffer, then move the swab up until it is resting on the sample solution, squeeze the swab from the outer tube wall in order to leave the sample in the tube as much as possible. Remove and discard the swab,cover the tube with the dropper. Open the aluminum foil pouch,take out the test cassette and lay it on a clean flat surface, add 4 drops (approximately 100 μL) processed sample extract into the sample well. The result should be observed within 15-20 minutes. Result observed after 20 minutes is invalid. 1.Kit Contents for Oral Secretion test 2.Insert the swab into the nasal cavity,gently spin and push the swab forward until blocked by turbinate. Then rotate and rub the swab on the cavity wall 3 times. 3.Tear the seal of sampling tubes containing individual lysis buffer. 4.Insert the swab into the sampling tube and rotate the swab against the inner tube wall 10 times 5.Squeeze the swab from the outer tube wall 5 times 6.Squeeze the swab from the outer tube wall 7.Cover the tube with the dropper 8.Add 4 drops processed sample extract into the sample well 9.Observe the results within 15-20 minutes

تاریخ : دوشنبه 22 اسفند 1401 نویسنده : panasoniccompressor l بازدید : 31

Personalization:

MIFARE and MIFARE Ultralight are registered trademarks of NXP B.V. and are used under license MIFARE Ultralight® MIFARE® Ultralight-based tickets offer an ideal solution for low-cost, high-volume applications such as public transport, loyalty cards. and event ticketing They serve as a perfect contactless replacement for magnetic stripe, barcode, or QR-code systems. The introduction of the contactless MIFARE Ultralight® ICs for limited-use applications can lead to reduced system installation and maintenance costs. MIFARE Ultralight C - Contactless ticket IC

NXP Semiconductors has developed the MIFARE Ultralight C - Contactless ticket IC MF0ICU2 to be used in a contactless smart ticket or smart card in combination with Proximity Coupling Devices (PCD). The communication layer (MIFARE RF Interface) complies to parts 2 and 3 of the ISO/IEC 14443 Type A standard

MIFARE RF Interface (ISO/IEC 14443 A) Contactless transmission of data and supply energy Operating distance up to 100 mm depending on antenna geometry and reader configuration Operating frequency of 13.56 MHz Data transfer of 106 kbit/s Data integrity of 16-bit CRC, parity, bit coding, bit counting True anticollision 7 byte serial number (cascade level 2 according to ISO/IEC 14443-3) Typical ticketing transaction: < 35 ms Fast counter transaction: < 10 ms 2.1 EEPROM 1536-bit total memory 512-bit compatible to MF0ICU1 36 pages, 1152-bit user r/w area Field programmable read-only locking function per block Field programmable read-only locking function per page for first 512-bit 16-bit one-way counter 32-bit user definable One-Time Programmable (OTP) area Write endurance 100000 cycles Data retention of 10 years

Events, concerts, park, etc

تاریخ : دوشنبه 22 اسفند 1401 نویسنده : panasoniccompressor l بازدید : 48

RFID wristband can be widely applied in swimming pool, theme park, marathon, hospital management, membership management and loyalty program and access control management etc. Besides, Meihe provides programming and encoding services which exactly fit customer’s programming or encoding requirements. Characteristics: 1_Excellent stability, resistant-heat, coming from its silicone material 2_Excellent waterproof can be used directly in water. 3_Circulation for many times after sterilization.

Advantages:

تاریخ : دوشنبه 22 اسفند 1401 نویسنده : panasoniccompressor l بازدید : 49

Products Descriptions:

HIGH QUALITY – This Animated Christmas Village Ferris Wheel with LED lights will decorate your home for seasons to come! MAKES A GREAT GIFT – This beautiful Lighted Winter Village Ferris Wheel will make a thoughtful gift for your family member or a friend. It will make a great addition to your Snow Village Collection, Christmas Village Collection or Christmas Tabletop Décor. SPECIFICATIONS – The Ferris Wheel gorgeously rotates with children joyfully riding .The Lights change their colors gracefully, adding a magical feel to it. A perfect reminder of those enchanting days at the Fair. Product size: 23x19x31.5CM. This Snow Village is operated with 3 x AA Battery (Not Included). PERFECT CHRISTMAS DÉCOR – This realistic Snow Village Figure is a perfect addition to your Santa Village Decorations. Bring the magic Christmas CERTIFIED-REACH/ROHS/EMC/LVD Features & Specifications: LED FERRIS WHEEL with moving kids *Item size: 23x19x31.5CM *Function: moving kids *Use Battery 3*1.5V AA, Not Include. *Material:Polyresin *Indoor use only Non-replaceable bulbs. IP20 * Christmas Village scene features Moving Ferris wheel. *Celebrate the beauty of Christmas with one of our lighted and animated holiday village scene decoration *Made of Polyresin. lights and animation make these holiday decorations a fun, unique conversation starter for any home. *Display anywhere as a fun accent decoration or use as a table centerpiece. makes a perfect addition to your Christmas village collection. *Liven up your holiday decor with one of our animated decorations. With lights and animation, these holiday village scene decorations are sure to draw attention in any home. Both the church and train station features intricate details and beautiful holiday lights to add some fun to your decorating.

تاریخ : چهارشنبه 10 اسفند 1401 نویسنده : panasoniccompressor l بازدید : 42

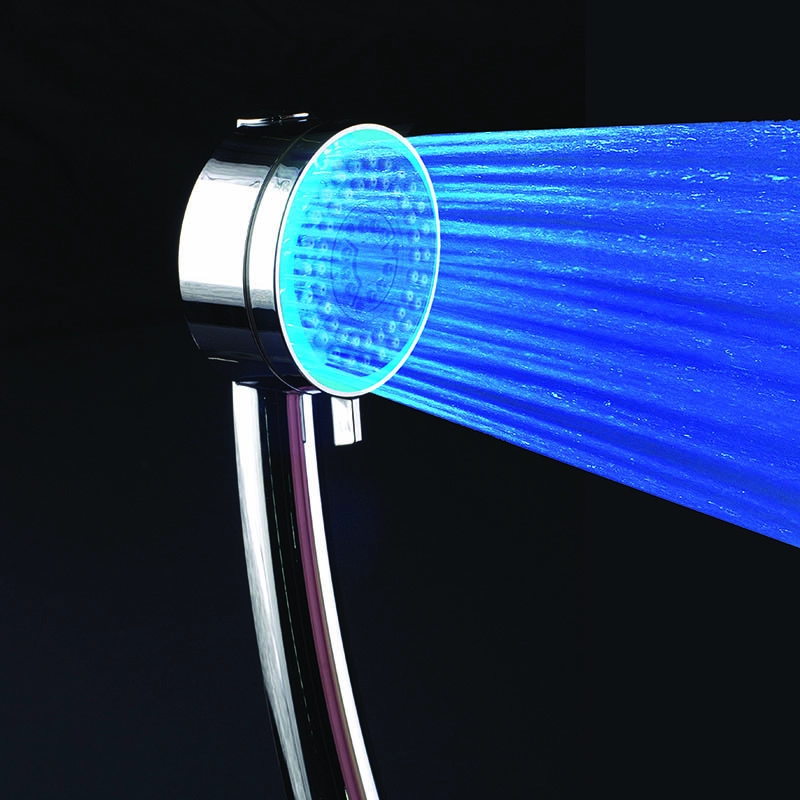

High Pressure Shower Head Double Boost Pressure Design. Hand Shower for bathroom solutions. OEM brand is acceptable. High Pressure Shower Head Double Boost Pressure Design for Low Water Pressure. General information about hand shower: 1. brass tube , dia.25mm*600mm 2. plasticbarsket , height adiustable 3. plastic soap dish 4. H2005 function hand shower 5. 1.5m double interlock brass hose

تاریخ : چهارشنبه 10 اسفند 1401 نویسنده : panasoniccompressor l بازدید : 36

Electronic bidet seat works with sensor Cabinet cistern. we can supply a whole solution for your bathroom Design. Electronic bidet seat works with sensor Cabinet cistern ! Shower Toilet offers you a complete installation with a large number of intelligent functions and, thanks to perfect technology, facilitates intimate hygiene. Experience after each use a feeling of fresh and pleasant freshness.This process is also more efficient and healthier than cleaning with toilet paper.

The expandable shower arm made of high quality stainless steel allows you to have hot water immediately and creates a soothing and soft effect. Theself-cleaning antibacterial nozzle has a pulsating and oscillating massaging jet for a pleasant wash. The water temperature and the jet intensity are adjustable. The shower arm is automatically cleaned with fresh water before and after each use. In order not to dirty it, the arm of the hand shower remains behind in the toilet bowl during the use of the toilet. Optimum hygiene thanks to perfect technology For your convenience, after the refreshing water rinsing, hot air dryer is at your disposal to eliminate unpleasant humidity. Its temperature is also adjustable. And do not worry about bad smells anymore As soon as you sit down on the toilet seat, the built-in fan automatically trips and diverts odors into the odor filter. The 180 ° Vortex rinse system provides deep cleaning. Water for rinsing comes from both sides of the toilet bowl without flange and thus reaches all areas. Dirt and limestone are unlikely to become embedded. The softclose toilet seat closes smoothly and quietly. For perfect hygiene, it is coated with an antimicrobial additive that leaves no chance for germs. Even after many cleaning with detergents, it does not lose its effectiveness.

تاریخ : چهارشنبه 10 اسفند 1401 نویسنده : panasoniccompressor l بازدید : 33

Heating Film is produced by accurate (under 1 micron) printing technology by coating carbon on PET film to radiate heat. Screen printing machine mainly deals with this process of printing carbon ink on PET substrate. Following Video show roll to roll screen printing machine print carbon ink for heating film products.

تاریخ : چهارشنبه 21 دی 1401 نویسنده : panasoniccompressor l بازدید : 44

Reflective material printing refers to printing on reflective materials such as reflective cloth, reflective film, reflective leather, reflective lattice, reflective gypsophila, etc.Reflective material printing can be widely used in: luggage, clothing, lighting, accessories, advertising and other fields. an appropriate printing method must be matched according to the needs of the printed matter. Printed products can receive the expected effect. Since the screen printing ink printing can be particularly thick, it is most suitable for printing with special effects. It is especially suitable for large quantities and thick ink colors. Let us see a sample picture shows screen printing effect on Reflective foil for road sign products We are proud to introuce that we have a good customer that in printing road sign with reflective film with Lingtie roll to roll screen printing machine . With the improvement of the urbanization level of various countries, the supporting facilities of urban roads are continuously improving, and one of the important signs is the standardization of road signs. Urban road signs mainly use engineering grade and high-strength reflective film with professional screen printing technology Below letter of recommendation is an affirmation of our machine .

تاریخ : چهارشنبه 21 دی 1401 نویسنده : panasoniccompressor l بازدید : 29

What is the development prospect of solar photovoltaic bracket? In the overall environment, in the context of the global energy market supply shortage, the energy shortage is becoming more and more serious, and new energy sources such as wind and solar energy have broad prospects. With the improvement of photovoltaic technology, the cost of photovoltaic power generation is constantly reduced, and the future of photovoltaic power generation has a broad space for growth. The global scale of new installed photovoltaic capacity continues to increase. As one of the key equipment of photovoltaic power stations, solar photovoltaic bracket will grow with the growth of new installed capacity of photovoltaic power stations around the world.

Photovoltaic bracket is also called solar photovoltaic bracket. Solar photovoltaic bracket is a special bracket designed to put, install and fix the solar panels in the solar photovoltaic power generation system.

Xiamen Reliance solar bracket making machine can customize a variety of supports to meet the diversified needs of the photovoltaic support market. Solar Racking Forming Machine:

Solar Panel Stand Rollformer Machine:

MORE Solar Structure Roll Forming Machine CAN CONTACT ME: https://www.asianrollforming.com/ WHATSAPP:+86 13850091540/ EMAIL:queenie@relianceprc.com

تاریخ : دوشنبه 19 دی 1401 نویسنده : panasoniccompressor l بازدید : 20

1.What is decoiler machine? If you look at the beginning of a roofing roll production line, you can see an evitable part of roll forming machine to hold and safely pay off the steel strip. A decoiler, also call uncoiler, unwinds steel coil, which can be fed into continuously running machineries such as roll formers or automatic plunches. Decoiler machine is suitable for all kinds of coil material feeding and the decoiler can work with straightener. Some decoiler models have speed control system and automatic or manual turning ability in both directions. Capacities of decoilers are variable. Stop systems can be friction or pneumatic 2.How decoiler machine working? The coil material will be placed on the coil car ofthe un-coiler to load into the mandrel where it is un-coiled to feed the cut to length or press line. The coil-loading car travels on the rail by hydraulic motor to reach the desired position. The coil is held by the mandrel hydraulically. The pneumatic pressure arm holds down the tip of the coil material at the beginning of the uncoiling. The coil loop is controlled by two photocells and ultrasonic sensor. 3.Uncoiler Machine's Application: Uncoiler and decoiler can be used for most of all roll forming machines such as: Roofing roll forming machine.Pressing curve forming machine .Floor deck roll forming machine. Truss roll forming machine ·Channel roll forming machine ·Ceiling roll forming machine ·Slitter & cutter We have suppplied standard decoiler and 3in1 precision feeder uncoiler, More deails can vist XIAMEN RELIANCE ROLL FORMING https://www.asianrollforming.com what's app:+86 13850091540

تاریخ : دوشنبه 19 دی 1401 نویسنده : panasoniccompressor l بازدید : 22

If you're usually a road rider, then this is for you. Riding on the road is a completely different game, and for your safety and overall experience, it pays to assess your habits and instincts when riding on rougher terrain compared to the road. The most common adjustments are: When cornering, push the off road motorbike down to the side, keeping your body as upright as possible, with your center of gravity moving forward over the fuel tank. This is to make the most of the tire tread and terrain working together for ultimate traction. The more these two things work together, the more control you'll have. Speed up in slippery or tricky areas like slits and sand. Unlike road riding, where you do the opposite (such as slow down an oil spill), you want to speed up to get through these areas as safely as possible. This will avoid getting stuck in dense sand or turning. Tire traction and terrain do not work the same as neatly laid asphalt, and if you try to slow down, it will have the opposite effect. See where you're going, not what you want to avoid – keep your eyes open! Although the same goes for road riding, your obstacles are not as obvious and predictable. You have to be more sensitive to where you want to go, because sometimes that gets around a tree... Leaning forward as far as possible when climbing hills and pulling your body weight back as much as possible on steep descents. This will help control the bike and again keep the tires on the terrain for better control. Remember, putting your foot on a nail is key! Dayun Motorcycle is an enterprise specializing in R&D, sales and service of street bikes, off-road motorcycle, scooters, cubs, tricycles and other products. We can provider professional off-road motorcycle for motocross enthusiast. Welcome contact us!

تاریخ : سه شنبه 01 آذر 1401 نویسنده : panasoniccompressor l بازدید : 29

Some people say that motorcycles are iron in meat, and it seems that they can kill you at any time. Danger is relative. For a senior motorcycle enthusiast, facing sudden danger can be minimized by some skills (except for ignoring traffic rules). In my opinion, a motorcycle is not a means of transportation, but an emotional travel partner who can accompany us to appreciate the scenery on the road and accompany us through the scenery. Maybe you will say that love does not need a reason, but there is always a reason why you choose to fall in love with it. Tell me why you choose a locomotive!

First of all, motorcycles can travel freely in congested cities to ensure timeliness. At present, the problem of urban congestion is becoming more and more serious, and many cars are only driven by the driver alone. In this way, the function of transportation is greatly reduced. Although public transportation is a highly respected mode of travel, it cannot meet the demand for time efficiency. Therefore, motorcycles have become the best choice for one-person or two-person travel.

Second, motorcycles have slowly evolved from a traditional concept of a single means of transportation to a way of life. High-quality recreational motorcycles allow those who like to pursue speed to find the driving pleasure that cannot be experienced from a car.

Furthermore, the current understanding of motorcycles has undergone fundamental changes. For example, riding a high-end motorcycle is more eye-catching than driving a high-end car. Of course, the price of high-end motorcycles is also relatively high. If you have high requirements for brands, you can focus on our "Universal" brand. We own a Classic 150cc Motorcycle that is perfect for your commuting needs. Classic 150cc motorcycle with large fuel tank is a true throwback motorcycle with modern technology and reliability. The motorcycle is perfect for both in town commutes and long-distance trips. For ordinary consumers, it can cost 20,000-30,000 yuan. Buy a motorcycle that can solve traffic jams and gracefully attend various occasions. The specifics can be considered based on the economic situation of each individual.

When people choose motorcycles, they basically get a convenient way to travel and are the best solution for urban commuting. In the process of motorcycle riding, many motorcycle friends made more new friends, shared the fun brought by motorcycle culture, and met the urgent needs of motorcycle enthusiasts. After being in contact with motorcycles for a period of time, some motorcycle friends even choose to ride motorcycles to find the "distant" in their dreams, and use motorcycles to interpret the splendor of life. With convenience, hobbies, and the ability to fulfill dreams, motorcycles are about to embark on a new historical stage and open up a new world in the field of transportation.

Sunny weather, longing for the distance, long-lost friends, everything, let's start with Dayun motorcycle riding!

تاریخ : سه شنبه 01 آذر 1401 نویسنده : panasoniccompressor l بازدید : 27

When looking up motorcycle specs, you'll often see engine displacement along with bore and stroke. The reality is that mentioning engine displacement can help you understand a motorcycle's engine and compare those figures to other motorcycles in the same class or series.

تاریخ : سه شنبه 01 آذر 1401 نویسنده : panasoniccompressor l بازدید : 34

A three wheeled cargo motorcycle is a versatile device that streamlines various delivery processes. The three-wheeled cargo motorcycle has a top speed of 25-80 kilometers per hour and is easy to handle, while also covering a lot of terrain. This type of vehicle will definitely benefit in busy urban areas, where it is difficult to find suitable parking spaces. Here are a few benefits of using a three-wheeled cargo motorcycle: Accept most of the goods This type of motorcycle is a versatile device capable of withstanding various loads. Some of the most common loads include fruit, wood, metals, coal, water, fertilizer, and grains. The carrying capacity of these vehicles can easily reach more than 1200 kg. The rear cargo area can be equipped with several different configurations to ensure that it is best suited to the intended load. Most of these vehicles have an open rear with a lifting mechanism for easy unloading when the goods arrive at the unloading point. It's ready to use These cargo vehicles are designed to be easily operated by anyone with past experience with motorized bicycles. These motorcycles include a standard electric/pedal start system with a 5-speed transmission and run on gasoline or gasoline fuel. Most riders can use this type of vehicle with only a short period of training. They are cheaper Three-wheeled cargo motorcycles are a lot cheaper than full-size delivery trucks. Many of these motorcycles cost between $600 and $1650 to provide an inexpensive solution to transport goods easily. In addition to the initial investment, ongoing repair and maintenance costs are often a fraction of what a truck would do on the road. Also, storage is not an issue because these vehicles are small, about 10-5 feet long and 4.5 feet wide. Whether transporting goods or passengers, motorized cargo tricycle offer a highly flexible mode of transportation that is ideal for light loads or driving on the most congested streets.

تاریخ : سه شنبه 01 آذر 1401 نویسنده : panasoniccompressor l بازدید : 32

Gas detection technology has a wide range of applications, in which a typical gas leak detection system is used to detect the tightness of the workpiece to be inspected. The external structure of the existing gas leak detection system includes several main components, such as an organic frame, a tracer gas source, a tracer gas inflation valve, a pressure sensor, a detection chamber, a leak detection valve, a return valve and a gas leak detector. One of the detection methods is the chamber type gas leak detection system. The chamber type gas leak detection technology generally uses halogen gas, hydrogen or helium as the tracer gas, fills the tracer gas into the workpiece to be inspected, and uses the gas leak detector to detect the concentration of the tracer gas outside the workpiece to be inspected. If the detected tracer gas signal exceeds the set value of the gas leak detector, it indicates that the workpiece is leaking. Chamber type gas leak detection system can be divided into vacuum chamber type gas leak detection system and atmospheric chamber type gas leak detection system. The working principle and structure of atmospheric chamber type gas leak detection system include tracer gas source, tracer gas inflation valve, detection chamber, leak detection valve, return valve and gas leak detector. The workpiece to be inspected is placed in the detection chamber, and the workpiece to be inspected is connected with the tracer gas source through the connecting pipe. During detection, after the door of the detection chamber is closed, the tracer gas inflation valve connecting the workpiece to be inspected is opened, and the tracer gas is filled into the workpiece to be inspected. The pressure sensor detects that after the inflation pressure in the workpiece to be inspected reaches a certain value, the tracer gas inflation valve is closed, and the leak detection valve and return valve are opened at the same time. If the workpiece to be inspected leaks, the gas in the workpiece to be inspected will overflow from the leak hole and enter the detection chamber under the effect of differential pressure. The gas leak detector samples from the detection chamber and judges whether the workpiece leakage exceeds the standard according to the size of the tracer gas signal obtained. For the vacuum chamber type gas leak detection system, there is a vacuum pump and a vacuum valve connected to the detection chamber. Before the tracer gas is filled, there is no need to vacuum the detection chamber for the atmospheric chamber type gas leak detection system. The main features of the chamber type gas leak detection system are high leak detection accuracy, fast production rhythm and simple operation. The sampling space of the chamber type gas leak detection system is the space of the detection chamber and the relevant pipe space connected with the gas leak detector. Before the tracer gas is filled in the chamber type gas leak detection system, the gas in the clean sampling space is the reference background, and the tracer gas signal left in the sampling space after detection is called background noise. The tracer gas in the background noise may leak into the sampling space from the gas leak detection system itself, or it is the residual accumulation of the previous detection. The background noise of the tracer gas will increase with the repeated operation of the system. When the background noise exceeds a certain level, it will lead to the failure of the leak detector to operate normally, and even lead to false judgment of the detection results. The existing technology cannot effectively eliminate the residual accumulation of tracer gas, and it is usually necessary to eliminate the impact of background noise through repeated empty machine operation. The equipment operation efficiency is low, resulting in energy waste.

تاریخ : سه شنبه 01 آذر 1401 نویسنده : panasoniccompressor l بازدید : 32

Gas detection technology has a wide range of applications, in which a typical gas leak detection system is used to detect the tightness of the workpiece to be inspected. The external structure of the existing gas leak detection system includes several main components, such as an organic frame, a tracer gas source, a tracer gas inflation valve, a pressure sensor, a detection chamber, a leak detection valve, a return valve and a gas leak detector. One of the detection methods is the gas hood type gas leak detection system. The gas hood type gas leak detection system uses halogen gas, hydrogen or helium as the tracer gas, fills the tracer gas into the detection chamber (i.e. the gas hood), and uses the gas leak detector to detect the concentration of the tracer gas in the workpiece to be inspected. If the tracer gas index is detected to exceed the set value of the gas leak detector, it indicates that the workpiece to be inspected has leakage. The working principle and structure of the above gas hood type gas leak detection system include a tracer gas source, a tracer gas inflation valve, a detection chamber (i.e. a gas hood), a workpiece connecting pipe, a leak detection valve, a return valve, and a gas leak detector. The backflow valve is connected with the gas leak detector, and the detection chamber is connected with the tracer gas source through the connecting pipe. After the door of the detection chamber is closed, the tracer gas inflation valve is opened, and the tracer gas is charged into the detection chamber. When the pressure sensor detects that the inflation pressure of the detection chamber reaches a certain value, the tracer gas inflation valve is closed. Open the leak detector and return valve. If the workpiece to be inspected leaks, the gas in the detection chamber (i.e. the gas hood) will overflow from the workpiece leak hole into the workpiece to be inspected under the effect of differential pressure. The gas leak detector samples from the internal space of the workpiece to be inspected, and judges whether the workpiece leakage exceeds the standard according to the size of the tracer gas signal obtained. The main features of the gas hood type leak detection system are high leak detection accuracy, fast production rhythm and simple operation. The sampling space of the gas hood type gas leak detection system is the internal space of the workpiece to be inspected, the workpiece connecting pipe and the relevant pipe space connected with the gas leak detector. Before the tracer gas is filled, the gas in the clean sampling space is the reference background of the gas hood type gas leak detection system, and the tracer gas signal remaining in the sampling space after detection is called background noise. The tracer gas in the background noise may leak into the sampling space from the gas leak detection system itself, or it is the residual accumulation of the previous detection. The background noise of the tracer gas will increase with the repeated operation of the system. When the background noise exceeds a certain level, it will lead to the failure of the leak detector to operate normally, and even lead to false judgment of the detection results. The existing technology cannot effectively eliminate the residual accumulation of tracer gas, and it is usually necessary to eliminate the impact of background noise through repeated empty machine operation. The equipment operation efficiency is low, resulting in energy waste.

تاریخ : سه شنبه 01 آذر 1401 نویسنده : panasoniccompressor l بازدید : 24

Steel cable drum roll forming machine. one main pulin with two shorts,curving cutting and cross joint.Higher efficieny relaince roll forming machines.

How is working? Related links: steel 4MM cable drum roll forming machine

تاریخ : سه شنبه 21 تیر 1401 نویسنده : panasoniccompressor l بازدید : 28

Flycutting corrugated roofring machine,0.15-0.3mm thickness with max line speed 50m/min. Smooth curving with multi-degree bend setting. No-stop-cutting corrugated roofing machine:

تاریخ : سه شنبه 21 تیر 1401 نویسنده : panasoniccompressor l بازدید : 28

مطالب گذشته

» Vacuum Transformer Oil Purifier to improve the quality of oil and extend life of power equipment »» سه شنبه 07 آذر 1402

» Transformer Oil Purification Machine Performance Advantage »» سه شنبه 07 آذر 1402 » Routine inspection of high-speed nail making machine »» دوشنبه 13 شهریور 1402 » 4 reasons why the nail making machine tool damages quickly nail making machine »» دوشنبه 13 شهریور 1402 » Where is the main demand for ultra-high speed nailing machine »» دوشنبه 13 شهریور 1402 » The Global Prospects of High-Speed Nail Making Machines »» دوشنبه 13 شهریور 1402 » High Efficient Double Stage Vacuum Transformer Oil Filtration Machine »» چهارشنبه 25 مرداد 1402 » How to Choose a Suitable Oil Pump for Vacuum Oil Purifier »» چهارشنبه 25 مرداد 1402 » Filtration Process of DVTP Vacuum Transformer Oil Purifier »» چهارشنبه 25 مرداد 1402 » Transformer Oil Purification Plant in Power Equipment Maintenance »» چهارشنبه 25 مرداد 1402 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| [ طراحی مجدد و ترجمه از : Ghaleb-Weblog.Ir ] [ طراح اولیه قالب ] | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||